By Gail Dutton

Advanced kinetic modeling (AKM) can accurately describe the complex behaviors of biologics, reducing risks from the developmental stage all the way through last-mile delivery. Importantly, regulators are beginning to consider this data.

“AKM provides us with stability data that otherwise would be available only at the end of stability evaluations,” Didier Clénet, principal scientist, global drug product bioprocess development and advanced analytics, Sanofi, tells GEN.

In a recent paper, Clénet and researchers from six prominent biopharma companies compared AKM predictions of shelf-life to real-time data for various types of vaccines and biotherapeutics. At temperatures of 5°C, stability predictions agreed with real-time stability data, although the AKM plots showed gentler slopes for antigen content during 12 months and for depolymerization for three years, and a virtually level line for number of colonies out to five years, than the more significant inclines or declines indicated by ICH methods.

Dramatic differences

At temperatures of 25°C and 37°C, however, the same model revealed dramatic differences. “Thanks to accelerated stability conditions, AKM was notably more accurate for long-term stability predictions at recommended storage conditions,” he says, than the shelf-life estimation methods recommended by the International Conference on Harmonization (ICH) guidelines. The increased accuracy is true for any biopharmaceutical and stability studies of a variety of critical quality attributes, he stresses.

The team says stability studies should include sophisticated models that go beyond simple linear regression. To use ADM, Clénet says, “Manufacturers should adopt good modeling practices and generate a minimum of 20 to 30 data points from at least three different temperatures for modeling. The selection of kinetic models that adequately describe the evolution of the considered quality attribute must be performed by screening Arrhenius-based equations of varying complexity and statistical analysis.”

Sanofi has used AKM modeling “for dose-saving of commercialized vaccines exposed to short temperature excursions during shipments and to accelerate technology transfers of well-known products or to extend their shelf-life without waiting for real long-term stability data,” Clénet says. This modeling approach also can accelerate the qualification process for new production sites for approved biopharmaceuticals.

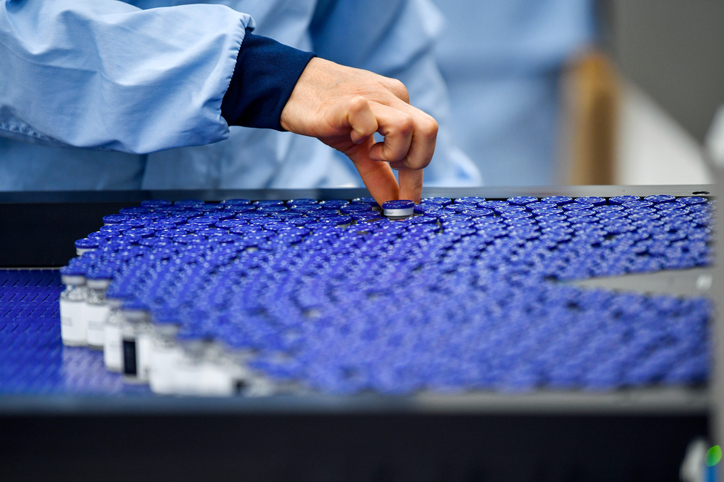

“AKM is a powerful tool to reduce development risks for any type of biopharmaceutical,” he says, noting that the European Medicines Agency (EMA) accepted Sanofi’s shelf-life estimation for its COVID-19 vaccine based on kinetic modeling and a few months of experimental stability data (followed by 12-month stability data when it became available). It also has accepted AKM to define acceptance criterion for a stability-indicating attribute for one of the company’s multivalent vaccines.

Globally, “AKM is being discussed by multiple stability working groups for integration into international guidelines,” Clénet adds.